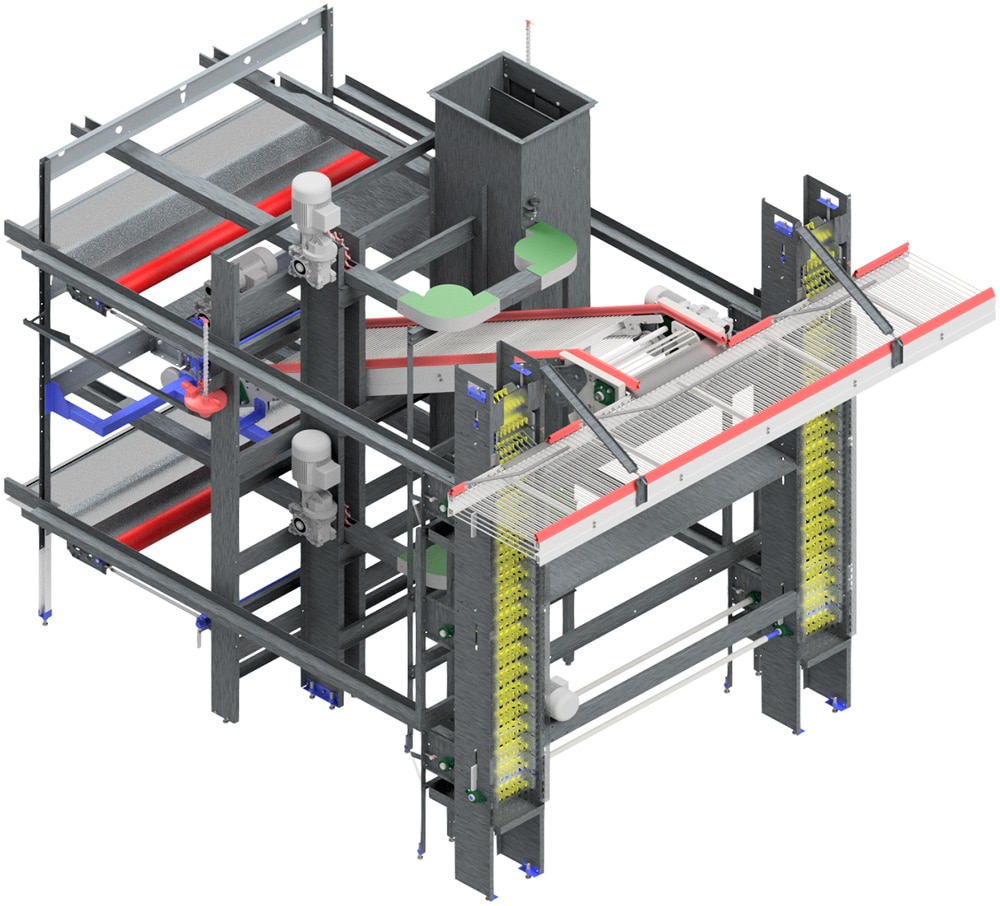

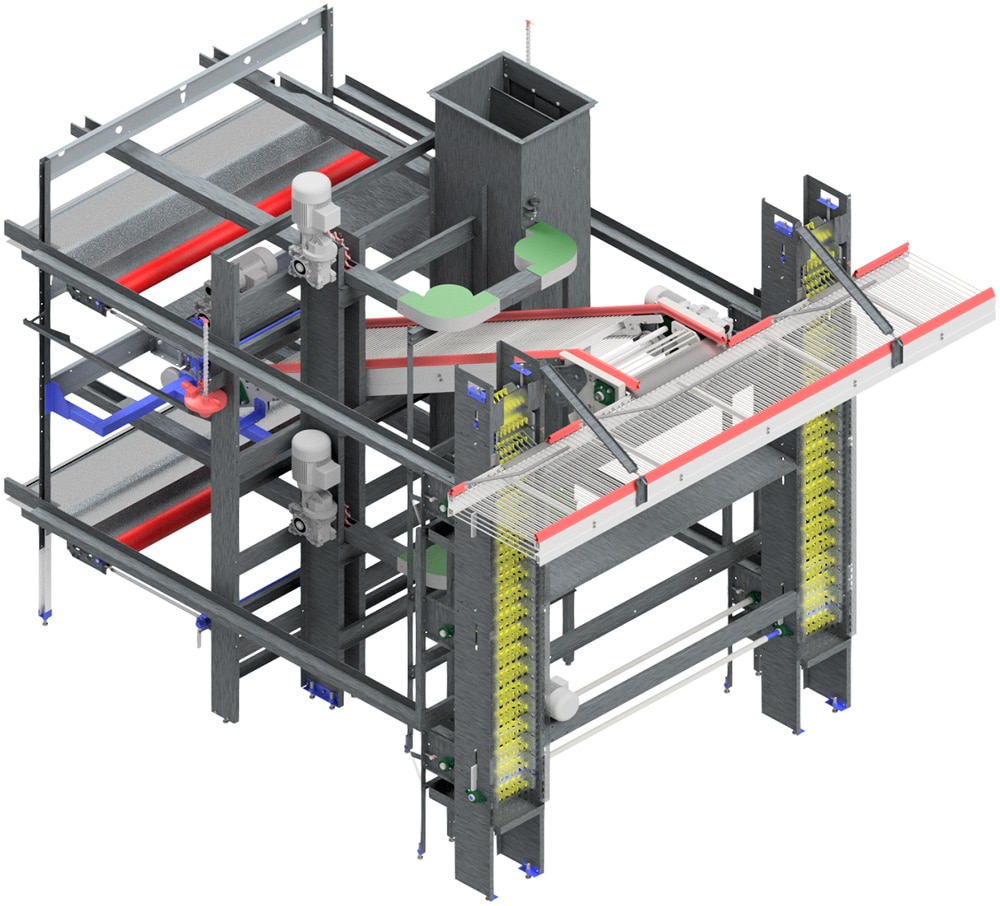

Central egg conveyor

Central egg conveyor

Adaptable equipment for the transporting of eggs from the production halls to the grading plant. Thanks to its flexibility, it can be adapted to any type of technology layout on the farm.

The width of the conveyors is from 300 to 1200 mm and the transport capacity is from 10 thousand to 120 thousand pieces/hour.

Adaptable equipment for the transporting of eggs from the production halls to the grading plant. Thanks to its flexibility, it can be adapted to any type of technology layout on the farm.

The width of the conveyors is from 300 to 1200 mm and the transport capacity is from 10 thousand to 120 thousand pieces/hour.

Main adavantages

- Main benefits: The distance between the crossbars allows a rising slope of up to 20°.

- Standard bends of 180°, 90° and 45° are available to create curves.

- Conveying capacity by conveyor width and speed.

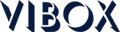

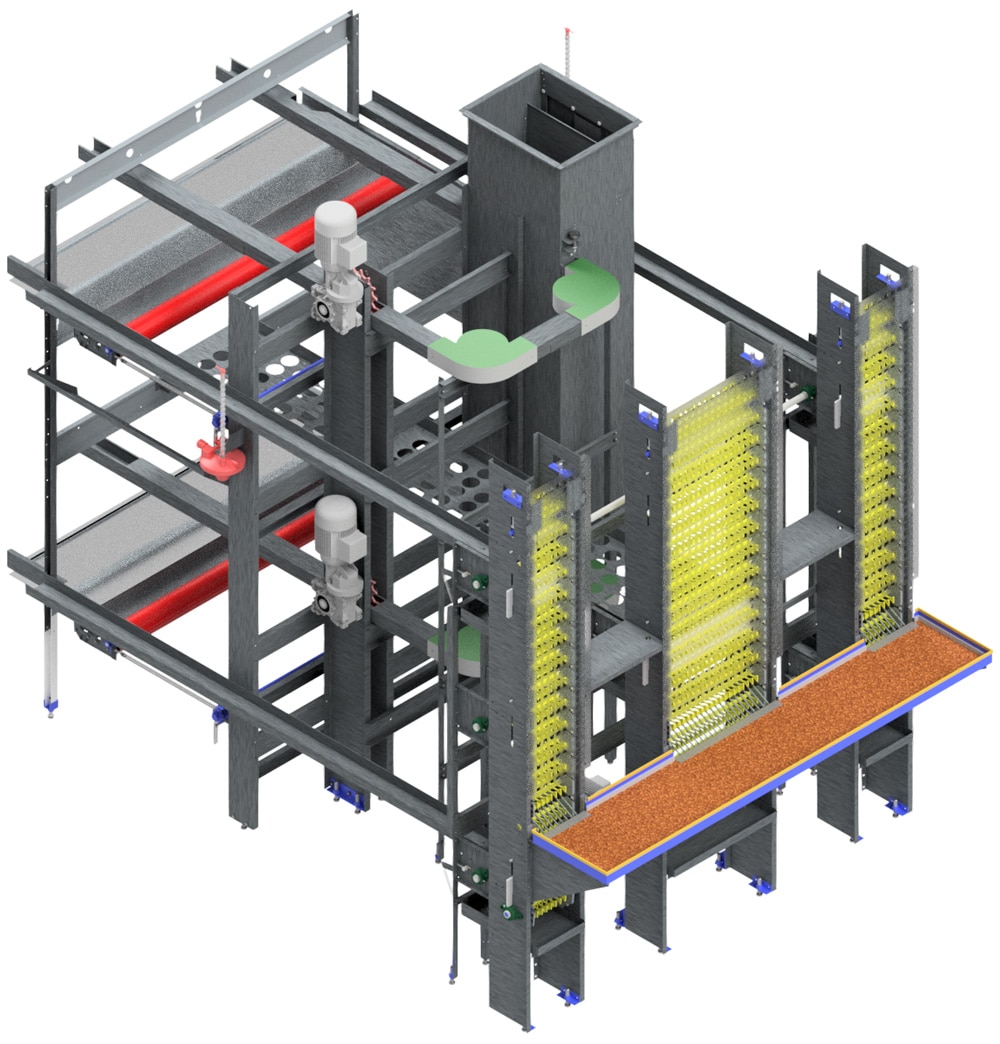

Egg Collector - SV

A stationary egg collector that removes eggs from each floor of the cage battery and moves them to a collection table or egg conveyor.

This is custom heading element

The device that moves the egg conveyor between the different floors of the cage technology allows the egg conveyors in the battery to be connected directly to the egg conveyor in the hall.

Eggs are collected simultaneously on each floor in all rows.

Main advantages

Main benefits: The elevator system is an egg collection system specially designed for the gentle transport of eggs, as there is only one transition between the conveyors.

The technology for rearing laying hens is fully accessible, because after all the eggs have been collected, the lift moves to a parking position that can be at a height of more than 2 m.

Another advantage is that the “lift system” occupies only a small space at the beginning of the rearing area, which increases the rearing space.

This system can be installed in the service room in front of the breeding area.

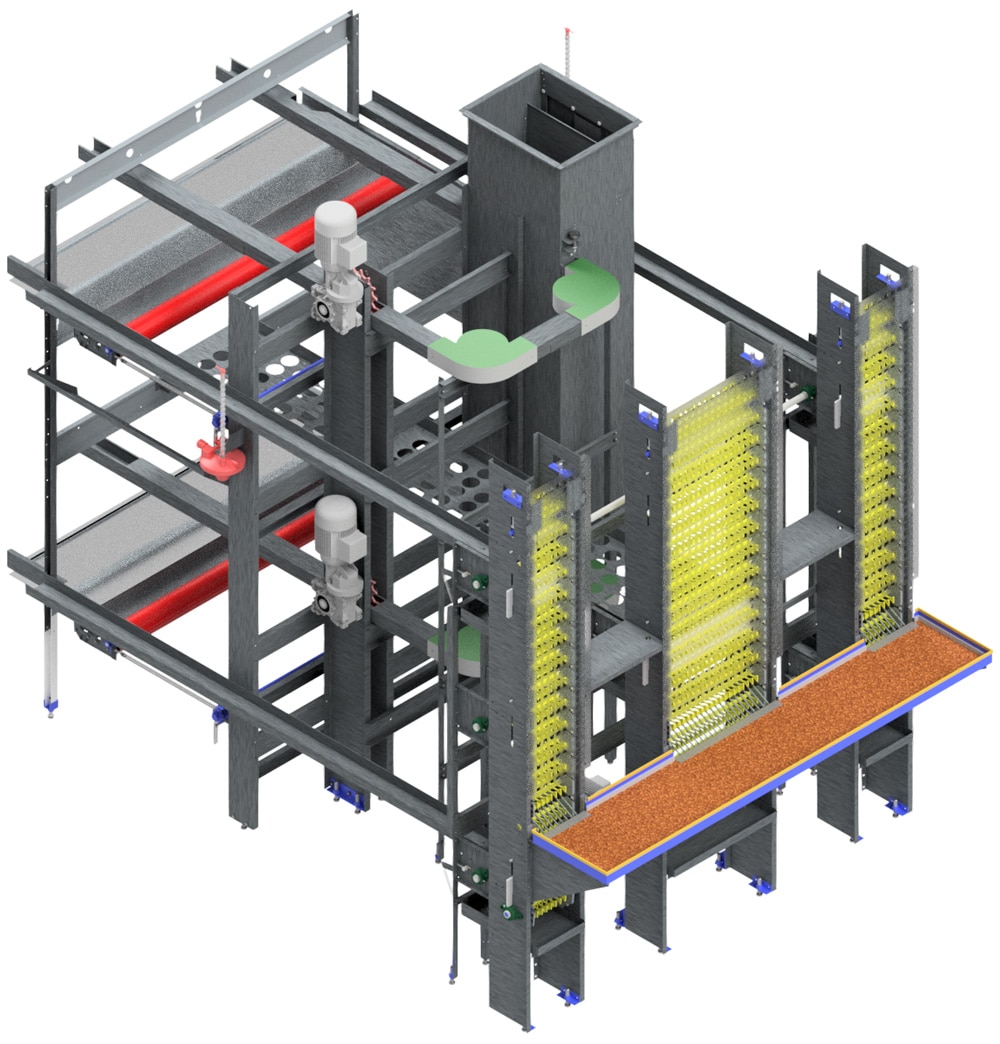

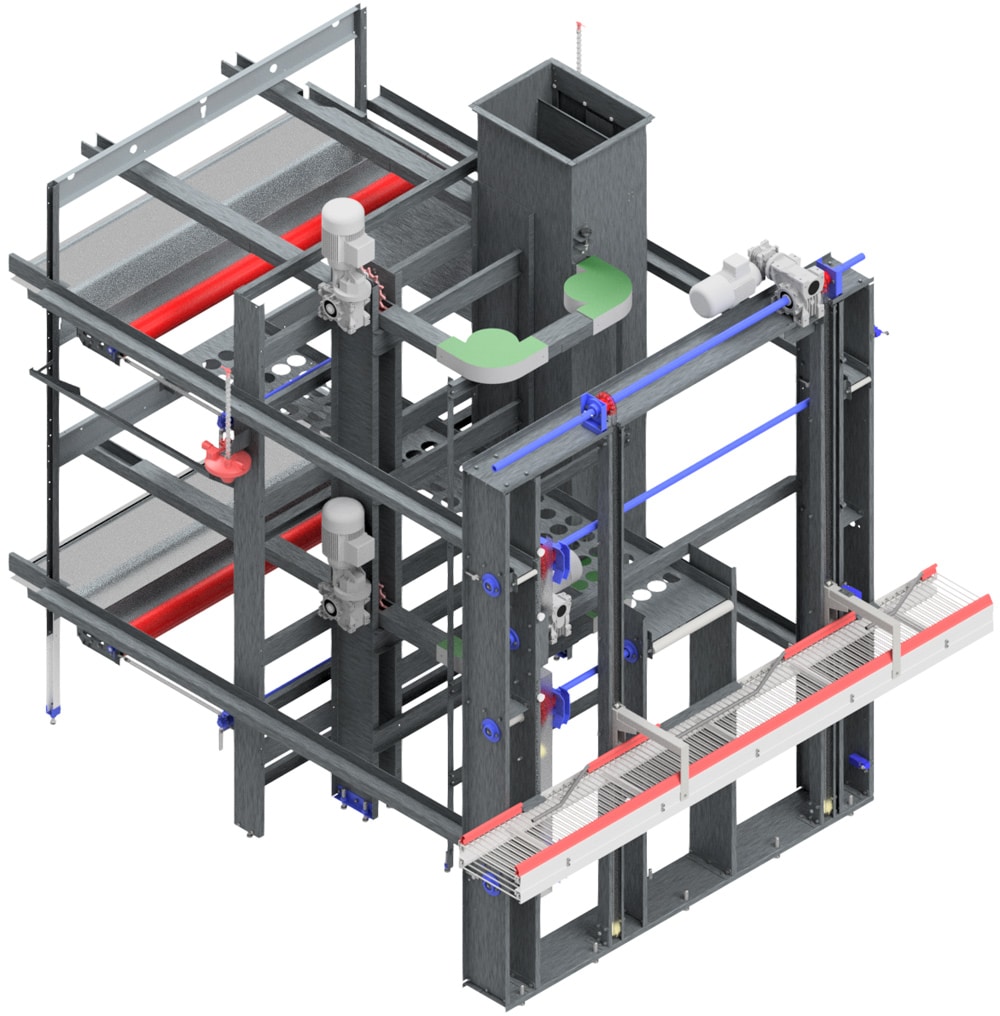

Vertical conveyors

Vertical conveyors replace the “standard” egg collectors on the hall. The most economical solution for collecting and transporting eggs on a central conveyor.

They work at a higher inclination than central conveyors and are available in widths of 400, 500 and 600 mm.

Main advantages

Low contamination and humpiness of eggs during transport.

The vertical conveyors are driven by a separate drive unit and therefore we can enjoy variable egg collection speeds by frequency control.

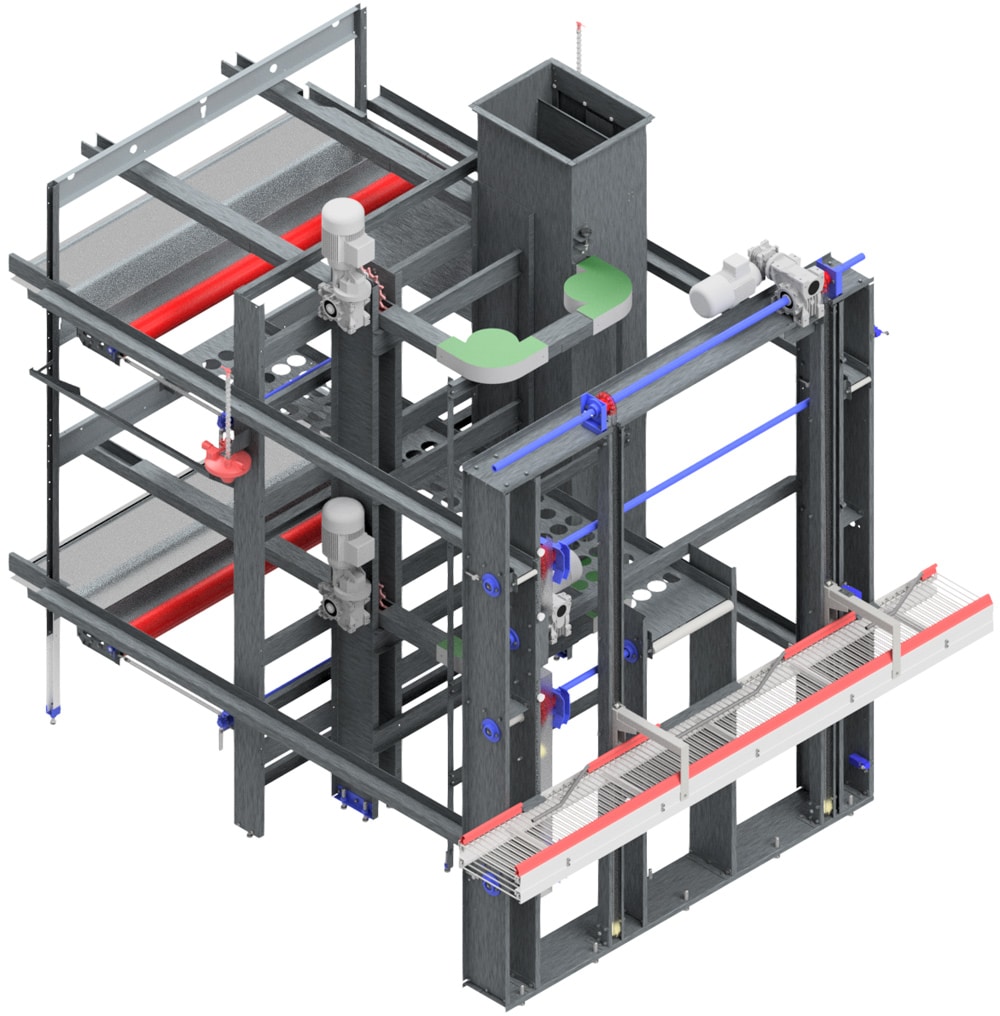

Egg Collector - SV

A stationary egg collector that removes eggs from each floor of the cage battery and moves them to a collection table or egg conveyor.

This is custom heading element

The device that moves the egg conveyor between the different floors of the cage technology allows the egg conveyors in the battery to be connected directly to the egg conveyor in the hall.

Eggs are collected simultaneously on each floor in all rows.

Main advantages

Main benefits: The elevator system is an egg collection system specially designed for the gentle transport of eggs, as there is only one transition between the conveyors.

The technology for rearing laying hens is fully accessible, because after all the eggs have been collected, the lift moves to a parking position that can be at a height of more than 2 m.

Another advantage is that the “lift system” occupies only a small space at the beginning of the rearing area, which increases the rearing space.

This system can be installed in the service room in front of the breeding area.

Vertical conveyors

Vertical conveyors replace the “standard” egg collectors on the hall. The most economical solution for collecting and transporting eggs on a central conveyor.

They work at a higher inclination than central conveyors and are available in widths of 400, 500 and 600 mm.

Main advantages

Low contamination and humpiness of eggs during transport.

The vertical conveyors are driven by a separate drive unit and therefore we can enjoy variable egg collection speeds by frequency control.